Magnesia iron spinel refractory brick is a basic refractory material without chrome, Magnesia-iron spinel bricks use high-purity magnesia sand and Al-Fe spinel sand as the main raw materials through reasonable proportioning, high-pressure pressed. It is a kind of no chromium environmental protection product.

The characteristics of magnesia iron spinel brick:

The characteristics of magnesia iron spinel brick:

It has the characteristics of high pressure resistance, excellent thermal stability, good thermal creep resistance, anti-erosion and infiltration capacity, high refractoriness under load. Beside, it has the property of more easily adhering coating than the direct bonded magnesia chrome brick, which effectively solve the problem of environmental pollution caused by the magnesia chrome brick generate hexavalent chromium during using procedure.

The advantages of magnesia iron spinel brick:

- Excellent adhering coating performance.

- Low thermal conductivity (1000℃,27w/m·k), small thermal expansion coefficient(1000℃,1..217%).

- Excellent structural flexibility, strong penetration resistance and anti-erosion to alkali salt content of K2SO4、Na2SO4、NaCl、KCl decomposed by cement material.

- High refractoriness under load, excellent thermal shock resistance, used in key parts of sp kilns and NSP kilns with high temperature ,fast speed, strong anti-erosion and great mechanical load.

Main application of magnesia iron spinel brick :

It is mainly used in the cement rotary kiln sintering zone.

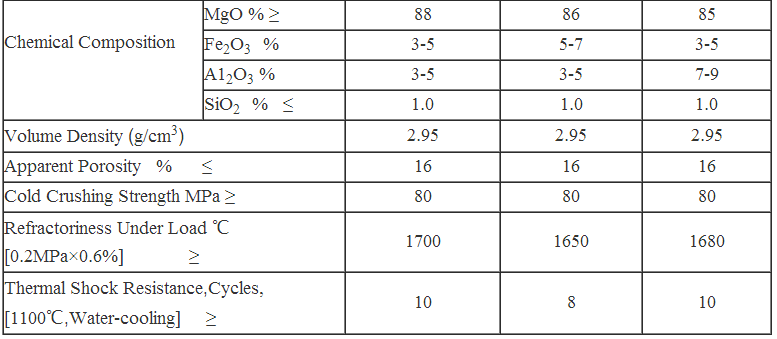

The physical and chemical index of magnesia iron spinel brick: